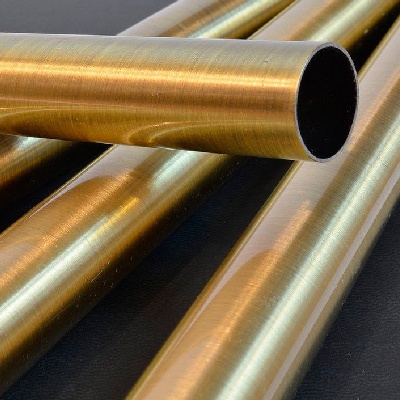

At Natron Steel, we are recognized globally as leading suppliers,

manufacturers, and stockists of Brass Pipes & Tubes, delivering

top-quality products across India and worldwide. Our brass pipes and tubes

are highly versatile, making them an essential component in various industries such as

pipe fittings manufacturing, furniture design, architectural projects, general

engineering, imitation jewelry, and lighting fixtures. These

products are also ideal for pipeline systems and heat exchanger

applications, available in various grades including

C230, C260, C330, and more, with customized sizes and wall thicknesses, all

offered at highly competitive prices.

Our Brass Seamless Pipes & Tubes are produced by extruding brass to the

desired length without any welded or forged cross-sections, ensuring uniform

strength throughout. These pipes are often threaded at one end, making them

perfect for applications requiring seamless integration. Brass Welded Pipes &

Tubes, on the other hand, are created from a strip that is rolled and welded,

offering a cost-effective solution and readily available in

continuous lengths.

Brass Pipes and Tubes, Brass Round Pipe, Brass Rectangle

Pipes Exporter, ASTM B135M Seamless Brass Pipes, Brass Alloy Square Pipes, Brass Finned

Pipes, ASTM B43 Brass Seamless Pipe, Brass Alloy Pipes, Brass Fabricated Pipes

Our brass alloys, a combination of copper, zinc, ferrous, and

lead, are lighter yet more durable than many other materials. These alloys

are perfect for industries like petrochemical, electrical

systems, automobile manufacturing,

condensers, and heat exchangers. The

small-diameter pipes are particularly suited for transporting

pressurized liquids, and they are widely used in residential water

supply systems, cooling and heating installations, and

commercial buildings. Moreover, Natron Steel’s Brass

Pipes are trusted in industries such as the pharmaceutical

sector, pulp and paper industry, offshore oil

drilling, power generation, and seawater

applications.

Brass Alloy Hot Rolled (HR) Pipes, Brass Welded Tubing,

Brass Cold Rolled (CR) Pipes, Brass Electropolished Pipes, Brass Cold Drawn Pipes, Brass

Hollow Tubes, Brass ERW Pipes, Brass Hexagonal Tubes, Brass EFW Pipes & Tubes, Brass Heat

Exchanger Tubing, Brass Rectangular Tubing

Brass Pipes Specifications

| Standard |

ASTM B 135 ASME SB 135 / ASTM B 36 ASME SB 36 |

| Dimension |

ASTM, ASME, and API |

| Size |

15mm NB to 150mm NB (1/2″ to 6″), 7″ (193.7mm OD to

20″ 508mm OD) |

| Tube Size |

6 mm OD x 0.7 mm to 50.8 mm OD x 3 mm thk. |

| Outer Diameter |

1.5 mm – 350 mm |

| Thickness |

0.3 – 9 mm |

| Form |

Round, Square, Rectangular, Hydraulic Etc |

| Length |

Double Random, Single Random, Cut Length |

| Types |

Seamless / ERW / Welded / Fabricated |

| Surface |

Black painting, varnish paint, anti-rust oil, hot galvanized, cold

galvanized, 3PE |

| End |

Plain End, Beveled End, Threaded |

Our commitment to excellence drives us to use the latest advanced

technologies in our manufacturing processes. With state-of-the-art equipment

and a team of dedicated professionals, Natron Steel

consistently delivers high-quality products that meet exact specifications.

We only use premium raw materials sourced from reliable vendors, ensuring

the rigid structure and longevity of our products. Every

step of our production process is carefully supervised by experts, with thorough testing

conducted to ensure our brass pipes perform beyond expectations, even in

the most demanding environments.

At Natron Steel, we maintain an extensive stock of brass

pipes and tubes, enabling us to meet our clients' needs promptly. We also offer

professional packaging solutions that ensure safe and secure delivery with

zero damage. Our fast and reliable shipping guarantees

that your orders are delivered within the shortest possible time, no matter the destination.

Choose Natron Steel for all your brass pipe and tube

needs, and experience unmatched quality, performance, and customer

service.

Brass Tubes Chemical Composition

| Brass |

Cu |

Fe |

Pb |

Zn |

| Min./Max. |

60.0-63.0 |

0.35 |

2.5-3.0 |

Rem. |

| Nominal |

61.5 |

– |

2.7 |

35.4 |

Brass Tubes Mechanical Properties

| Mechanical Properties |

English |

Metric |

| Hardness, Brinell |

37.0 – 155 |

37.0 – 155 |

| Hardness, Rockwell H |

46.0 – 90.0 |

46.0 – 90.0 |

| Hardness, Rockwell 30T |

8.00 – 240 |

8.00 – 240 |

| Hardness, Vickers |

80.0 – 140 |

80.0 – 140 |

| Hardness, Rockwell F |

54.0 – 100 |

54.0 – 100 |

| Tensile Strength, Yield |

5000 – 99100 psi |

34.5 – 683 MPa |

| Charpy Impact |

11.1 – 75.0 ft-lb |

15.0 – 102 J |

| Hardness, Rockwell B |

12.0 – 133 |

12.0 – 133 |

| Tensile Strength, Ultimate |

3000 – 150000 psi |

20.7 – 1030 MPa |

| Elongation at Break |

1.00 – 68.0 % |

1.00 – 68.0 % |

| Modulus of Elasticity |

11000 – 17600 ksi |

75.8 – 121 GPa |

| Reduction of Area |

40.0 – 60.0 % |

40.0 – 60.0 % |

| Compressive Yield Strength |

9000 – 375000 psi |

62.1 – 2580 MPa |

| Fatigue Strength |

3190 – 52200 psi |

22.0 – 360 MPa |

| Poissons Ratio |

0.260 – 0.460 |

0.260 – 0.460 |

| Machinability |

20.0 – 106 % |

20.0 – 106 % |

| Shear Strength |

29700 – 77000 psi |

205 – 531 MPa |

| Shear Modulus |

3900 – 6400 ksi |

26.9 – 44.1 GPa |

| Izod Impact |

8.00 – 33.2 ft-lb |

10.8 – 45.0 J |

Brass Pipes and Tubes Physical Properties

| Properties |

US Customary |

| Modulas of Elasticity in Tension |

14000 ksi |

| Melting Point -Solidus |

1630 F |

| Density |

0.307 lb/in3at 68 F |

| Electrical Conductivity |

26 %IACS @ 68 F |

| Melting Point -Liquidus |

1650 F |

| Electrical Resistivity |

39.90 ohms – cmil/ft @ 68 F |

| Thermal Conductivity |

67 Btu · ft/(hr · ft2·oF)at 68F |

Brass Pipe Price List

| Schedule |

Nominal Size |

Price in USD |

Price in INR |

| Schedule 40 |

0.375″ |

$28.63 |

₹ 2380.89 |

| 0.125″ |

$15.04 |

₹ 1250.74 |

| 1.25″ |

$113.06 |

₹ 9402.15 |

| 0.25″ |

$34.40 |

₹ 2860.73 |

| 0.75″ |

$56.37 |

₹ 4687.77 |

| 0.375″ |

$28.63 |

₹ 2380.89 |

| 2.5″ |

$935.70 |

₹ 77813.51 |

| 1″ |

$102.57 |

₹ 8529.80 |

| 3″ |

$457.74 |

₹ 38066.00 |

| 2″ |

$177.78 |

₹ 14784.32 |

Brass Pipe Weight Chart

| Regular Brass Pipe Weight |

| Pipe Size (in) |

Dimensions Inch |

Pounds per Linear Foot |

| I.D. |

O.D. |

Wall Thickness |

Red Brass |

| 1/4″ |

0.376 |

0.540 |

0.082 |

0.447 |

| 1/8″ |

0.281 |

0.405 |

0.062 |

0.253 |

| 3/4″ |

0.822 |

1.050 |

0.114 |

1.27 |

| 1/2″ |

0.626 |

0.840 |

0.107 |

0.934 |

| 3/8″ |

0.495 |

0.675 |

0.090 |

0.627 |

| 1″ |

1.063 |

1.315 |

0.126 |

1.78 |

| 6″ |

6.125 |

6.625 |

0.250 |

19.0 |

| 1-1/2″ |

1.600 |

1.900 |

0.150 |

3.13 |

| 1-1/4″ |

1.368 |

1.660 |

0.146 |

2.63 |

| 2-1/2″ |

2.501 |

2.875 |

0.187 |

5.99 |

| 2″ |

2.063 |

2.375 |

0.156 |

4.12 |

| 3″ |

3.062 |

3.500 |

0.219 |

8.56 |

| 4″ |

4.000 |

4.500 |

0.250 |

12.7 |

| 3-1/2” |

3.500 |

4.000 |

0.250 |

11.2 |

| 5″ |

5.063 |

5.563 |

0.250 |

15.8 |

| Extra Strong Brass Pipe Weight |

| Pipe Size (in) |

Dimensions Inch |

Pounds per Linear Foot |

| I.D. |

O.D. |

Wall Thickness |

Red Brass |

| 3/4″ |

0.736 |

1.050 |

0.157 |

1.67 |

| 1/4″ |

0.294 |

0.540 |

0.123 |

0.611 |

| 3/8″ |

0.421 |

0.675 |

0.127 |

0.829 |

| 1/8″ |

0.205 |

0.405 |

0.100 |

0.363 |

| 1/2″ |

0.542 |

0.840 |

0.149 |

1.23 |

| 1″ |

0.951 |

1.315 |

0.182 |

2.46 |

| 2″ |

1.933 |

2.375 |

0.221 |

5.67 |

| 1-1/4″ |

1.272 |

1.660 |

0.194 |

3.39 |

| 2-1/2″ |

2.315 |

2.875 |

0.280 |

8.66 |

| 1-1/2″ |

1.494 |

1.900 |

0.203 |

4.10 |

| 3″ |

2.892 |

3.500 |

0.304 |

11.6 |

Brass Pipe and Tube HSN Code

| Type |

HS Code |

| Brass Tube |

74199930 |

| Brass Pipe |

74112100 |